Production engineering

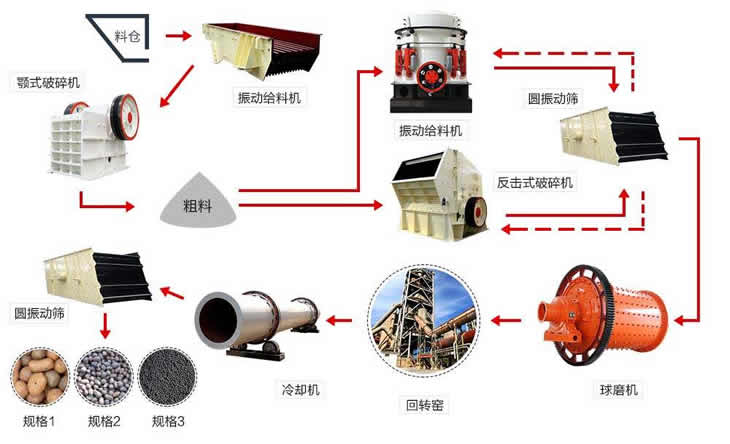

Raw material mixed grinding granulation burning swelling stowage transportation

In the production of fly ash ceramsite, the rotary kiln should be used, that is, the preheating section and drying section of the kiln body can be controlled separately, and the ceramic particles produced in Ningbo Chinese language can be controlled according to the state of raw materials. Clay ceramsite has been banned from production and use in some areas in recent years due to the limitation of land resources. But some areas can use river silt, waste mountain soil and so on to carry on the production. The process is as follows: raw material agitation-granulation-screening-sintering-stacking-transport .

In operation, we should pay attention to lookout to prevent material from forming in the kiln and affect the quality.

Industrial rotary kilns are used in the production equipment of ceramsite in China. The cylinder-shaped main kiln is placed on the roller at a angle of about 3 °. The material enters the kiln at the high end, and under the action of rotary movement of the kiln body, the material rolls from the height (the kiln end) to the low place (the kiln head), and at the kiln head, the high-pressure fan injects the pulverized coal (or other fuel, such as natural gas) into the kiln, The heat produced by the combustion can cause physical and chemical changes of the material and the phenomenon of expansion, which can be changed into ceramsite after cooling.

Production facility

The main equipment for producing ceramsite mainly includes: raw material storage bin, dust chamber, induced draft fan, main kiln body, coal injection system, control cabinet and so on.

Production of shale ceramsite auxiliary equipment: crusher, screening machine, belt conveyor, feeder, discharging machine and so on.

The auxiliary equipments for producing fly ash and clay ceramsite are wheel mill, two-axis mixer, granulator, screen machine, belt feeder and so on.

Shale

Mining-primary crushing-secondary crushing-screening-temporary storage-feeding-Sintering-Product grading screening-stacking-Transport.

In operation, we should pay attention to the matching relationship between feed quantity, coal quantity, rotary speed of kiln body and air quantity, so that they can be adjusted to the best technological condition.

The production of a set of ceramsite from fly ash and other industrial waste residues has been a research topic for many years. Nowadays, high-strength and light-weight fly ash ceramsite has been successfully developed, and its performance indexes are superior to those of shale and clay ceramsite. Adhesives, expanding agents and mineralizer, etc. the composition of fly ash with different components is also different.

More information of the Ceramsite Processing Line, PLS contact me:

TEL:0086 18568631888

WS:0086 13663831568

E-mail:tongjiagroup@163.com