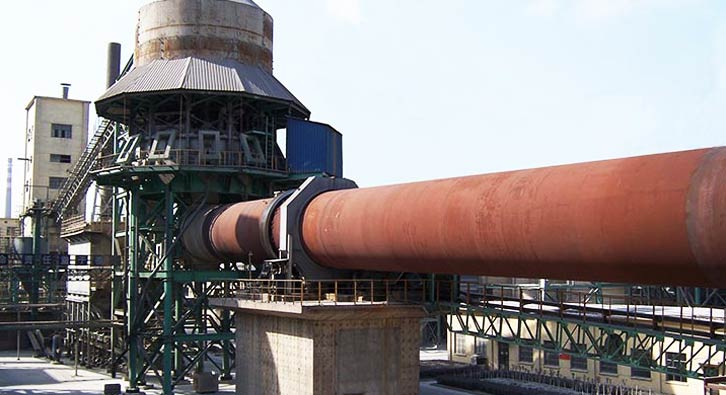

Description

The kaolin rotary kiln is one of the important equipments in the kaolin sintering process. Because of the physicochemical properties of kaolin, the required temperature of the kiln is more than 950 ℃. Kaolin rotary kiln also known as kaolin calcination kiln, in addition to calcining kaolin, but also for bauxite calcination, zinc oxide calcination, magnesium oxide calcination. Kaolin has the characteristics of high whiteness, easy dispersion in water and soft quality. It has good plasticity, excellent electrical insulation, good acid solubility, good fire resistance, high adhesion, low cation exchange capacity and so on.

Calcination of ultrafine kaolin in medium temperature rotary kiln is an advanced and mature technology in China, which represents the development direction of calcination technology of ultrafine kaolin. After dehydration, decarbonization and whitening, the product has stable performance, high calcination yield and low energy consumption. Finished kaolin is a necessary mineral material for national defense, medicine, chemical industry, ceramics, rubber, paper making and so on. This also makes the standardized production of kaolin more important. Many high-tech fields in China also began to use kaolin as a new material, and even the ceramic parts of the space shuttle for high temperature resistance were also made of kaolin.

Working principle:

Kaolin rotary kiln operates slowly under heavy load and alternating speed at high temperature. The maintenance of accessories and the level of thermal control are related to the safety and efficiency of rotary kiln operation. The maintenance of the transmission device is focused on the lubrication, running state, dynamic detection and meshing accuracy of the gear, and the installation accuracy of the supporting device determines whether the rotary kiln can operate safely and reliably. In operation, attention should be paid to the distribution of bearing capacity, the arrangement of the supporting wheel, the upward and downward pressure and time of the hydraulic gear, the bearing force of the wheel, the gap between the wheel and the pad. The sealing device directly affects the thermal system and operation cost of rotary kiln. Strengthened return Daily maintenance of rotary kiln data analysis, conducive to the management of equipment.

Characteristic:

A, using the most advanced hydraulic gear device at home and abroad.

B, the piston pump with high measuring precision.

C, high-precision speed control valve and contact graphite block sealing device and other advanced technology in China.

D, easy to operate, reliable use.

E, stabilizes the thermal system and improves the operating rate of the equipment.

F, compared with the same specification equipment, the operating rate increased by 10 percent, the output increased by 5-10, and the heat consumption decreased by 15.

Purpose:

Kaolin has two main fields in papermaking industry, one is filler used in papermaking (or papermaking) process, the other is pigment used in surface coating process.

Parameter:

|

Specification(m) |

Capacity(t/d) |

Main Motor |

Main reduce motor |

Weight(t) |

|

Model |

Power(kw) |

Model |

Speed Ratio |

|

φ18x26 |

72 |

JZT2-72-4 |

30 |

JZQ750-1-Ⅰ |

48.57 |

66 |

|

φ1.9/1.6x39 |

72 |

JZT2-72-4 |

30 |

JZQ750-1-Ⅰ |

48.57 |

66 |

|

φ1.9x36 |

84 |

YCT315-4A |

37 |

ZS110-5-Ⅲ |

78.19 |

85.9 |

|

φ2.2x45 |

98.4 |

JZT82-6 |

55 |

ZA125 |

93.93 |

104 |

|

φ2.5x40 |

160 |

Z2--92 |

40 |

ZS125-2-Ⅰ |

134.9 |

143 |

|

φ2.5x45 |

170 |

JTZ82-4 |

45 |

ZS125-4-Ⅰ |

69.71 |

148 |

|

φ2.5x50 |

180 |

ZT3-72-4 |

30 |

ZS145-9-Ⅴ |

122.8 |

173 |

|

φ2.5x60 |

168 |

YCT355-4B |

75 |

ZS165-7-Ⅱ |

99.96 |

222 |

|

φ3x48 |

360-480 |

YCT355-4B |

75 |

ZS145-7-Ⅱ |

100.4 |

170.6 |

|

φ3.1/2.5x78 |

216-240 |

Z4—225-31 |

75 |

ZS165-2-Ⅱ |

57.17 |

268 |

|

φ3x48 |

700 |

ZSN4-280-21B |

110 |

MSY56-28-Ⅱ |

28 |

244 |

|

φ3x100.94 |

450 |

ZSN4-280-21B |

90 |

NZS995-90-Ⅵ-L |

90 |

526 |

|

φ3.2x50 |

1000 |

ZSN4-280-21B |

160 |

MSY56-28-Ⅱ |

28 |

252.4 |

|

φ3.2x52 |

600 |

ZSN4-280-21B |

125 |

ZSY1110-71BL |

71.54 |

275 |

|

φ3.3x52 |

1000 |

ZSN4-280-11B |

125 |

NZS995-40-Ⅵ-BR |

40 |

283 |

|

φ3.5x52.5 |

1400 |

Z2-112 |

180 |

ZS177 |

79.22 |

360 |

|

φ3.5x54 |

1500 |

ZSN4-3156-092 |

220 |

ZSY500-40-Ⅴ |

40 |

368 |

|

φ3.6x70 |

490 |

ZSN4-280-11B |

125 |

ZS177-5-Ⅱ |

79.2 |

419 |

|

φ3.95x56 |

2000 |

Z4-280-32BTH |

250 |

ZSY560-40-Ⅰ |

40 |

417 |

|

Φ4x28 |

90 |

ZSN4-280-21B |

160 |

ZSY500-71-Ⅳ |

71 |

300 |

|

φ4x60m |

2500 |

ZSN4-355-09Z |

315 |

ZSY630-35.5-Ⅰ |

34.6 |

523 |

|

φ4.2x60m |

2800 |

ZSN4-355-12 |

420 |

ZSY710-35.5-Ⅰ |

35.5 |

--- |

|

φ4.3x60m |

3000 |

ZSN4-355-12 |

375 |

ZSY710-40 |

40 |

553 |

|

φ4.8x75m |

5000 |

ZSN4-400-92 |

630 |

JH710-40 |

42 |

841 |

More information of the Kaolin Rotary Kiln PLS contact me:

TEL:0086 18568631888

WS:0086 13663831568

E-mail:tongjiagroup@163.com