The phenomenon of partial fire in lime kiln equipment is a relatively difficult problem, and it is impossible for many novice technicians to start, so the editor of Tongjia Industry will share some basic operations and concepts with you for the phenomenon of partial fire.

Lime kiln equipment has been available for a long time. Several important reasons for the partial fire of the lime kiln have been summarized in the long-term use of many cooperative lime kiln production lines. If these aspects are protected, the phenomenon of partial fire can basically be avoided:

The fundamental reason for the partial fire of the lime kiln is uneven ingredients, uneven cloth, poor ventilation, and unilateral discharge.

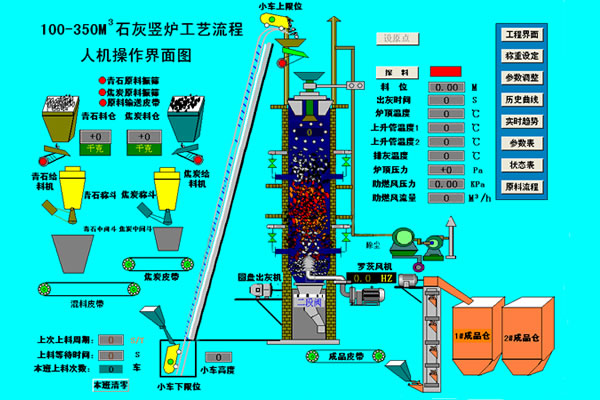

1. Uneven ingredients: Use an electronic speed-adjusting belt scale to scientifically mix standard anthracite and raw limestone by setting parameters. Generally, the output of lime kiln equipment will be designed to scientifically mix coal and stone according to your standard anthracite heat release.

2. Uneven distributing: the lime kiln mixed material enters the top of the kiln for distributing through the automatic rotating distributor. During this period, the distributing effects of the automatic rotating distributors produced by different manufacturers are not the same. If the distributing is uneven, it will also cause the lime kiln. Partial fire phenomenon.

3. Obstructed ventilation: Choose a professional probability hood, choose the corresponding type of frequency conversion fan according to the diameter, raw material, output of the lime kiln (of course, if the budget is sufficient, you can choose the Roots blower to be more stable), and accurately and stably control the air volume and pressure. Whether you choose a fan with low air volume and low air pressure, or use a low air pressure and high air volume

For fans, the air volume should be calculated according to the feed volume per unit time designed by the lime kiln, and the ventilation resistance should be calculated according to the particle size of the selected limestone and coal to determine the appropriate air pressure of the fan. When installing the lime kiln fan, it is equipped with a professional lime kiln air control frequency converter, which can adjust the air volume appropriately according to the lime kiln calcination condition.

4. Unilateral unloading: Choose a lime kiln unloader according to the output, kiln diameter, raw materials, etc. of the lime kiln. The unloading methods of the lime kiln include circular polygonal, disc, ram, etc., and several unloading methods have their own merits. The specific selection needs to be selected according to the design requirements of the specific lime kiln.

The above are the four situations in which lime kiln equipment avoids partial fire. If you want to know more about the production line of lime kiln equipment, you can contact our Tongjia Industrial Lime Kiln Office.