The process of calcining lime in the lime kiln is very long since the history of earth kilns in our country. With the continuous changes in the calcination process, the quality of the calcined lime is getting higher and higher, and the calcining output of the lime production line is also getting higher and higher. Therefore, the new lime kiln calcination process And equipment continues to promote the rapid development of the lime kiln calcination industry.

The new environmentally friendly lime kiln calcining process is improved and more scientifically designed on the basis of the original mechanical lime kiln calcining process. The calcination principle is roughly the same. Let’s take a look at the new environmentally friendly lime kiln calcining process:

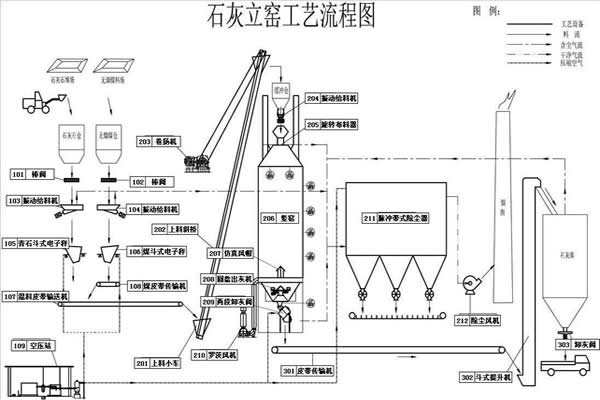

1. Pile up limestone and standard anthracite raw materials after strict screening.

2. Feed into the limestone raw material warehouse and standard anthracite fuel warehouse by forklift or other feeding devices.

3. Set the parameters of belt weighing scale, and realize raw material mixing through belt weighing scale.

4. The standard mixed material is sent to the feeding trolley through the conveyor belt.

5. The feeding trolley moves towards the top of the kiln through the hoist and diagonal brace, and merges into the kiln top distributor silo.

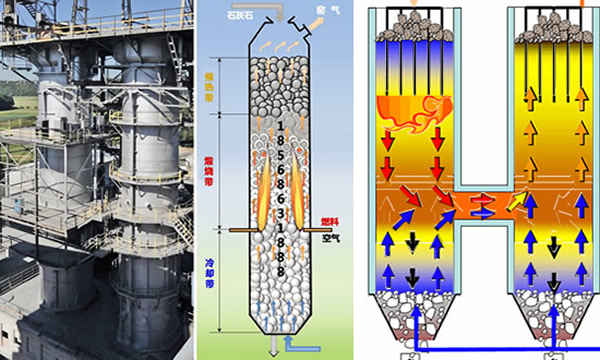

6. The kiln top distributor can evenly and reasonably arrange the raw materials in the upper silo to the lime kiln pre-heating zone by automatically rotating the cloth.

7. The lime kiln preheating zone begins to preheat from room temperature to 850 degrees Celsius, and gradually enters the lime kiln calcining zone.

9. The cooling belt quickly cools the high-temperature red lime through the cold air. While the lime is cooling down, the cold air heats up and enters the bottom of the lime kiln to act as combustion-supporting air. After that, the lime enters the screening equipment for large and small particle classification and enters the designated through the conveyor belt. Of finished lime products in the warehouse.

The calcination sequence of the new environmentally friendly lime kiln calcination process is basically unchanged, but the equipment in the lime production line has been upgraded and improved, and the parameters in the calcination system are more accurate. This not only ensures high quality and high yield of lime, but also reduces the energy of the lime kiln. Consumption and reduce the environmental pressure of lime kiln exhaust gas from the root.