Features

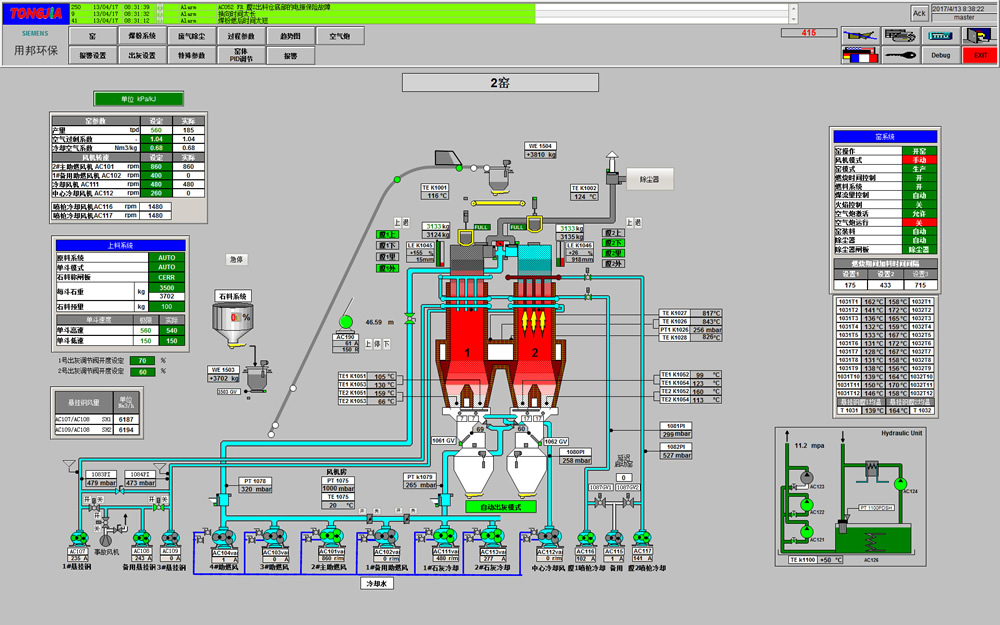

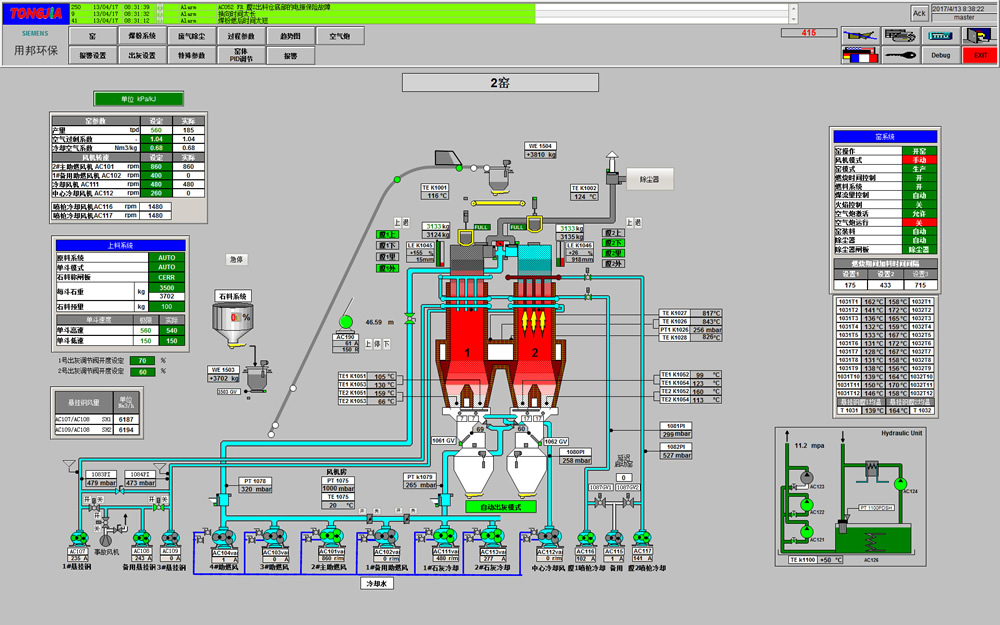

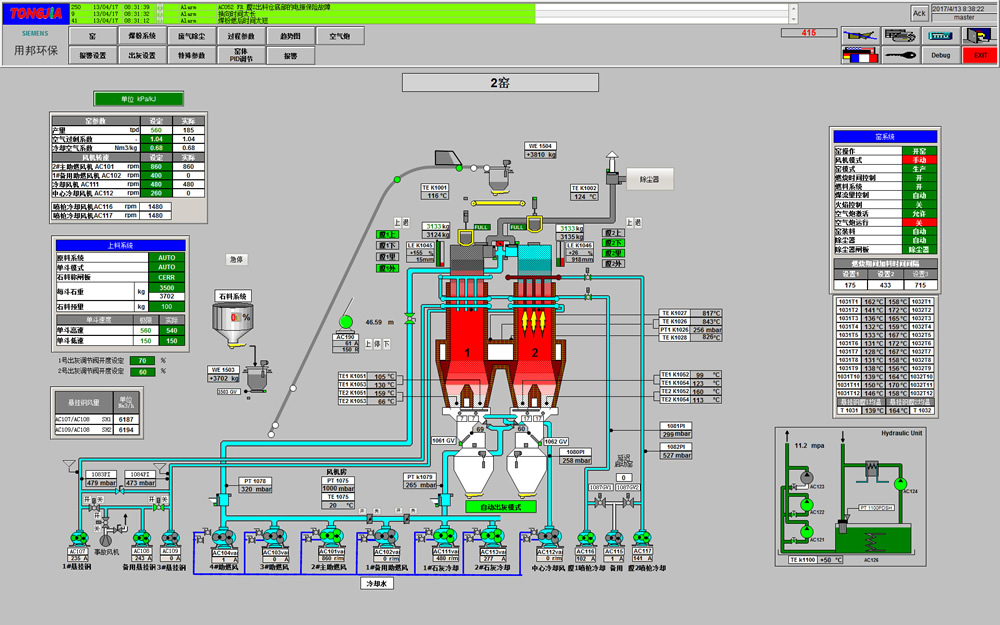

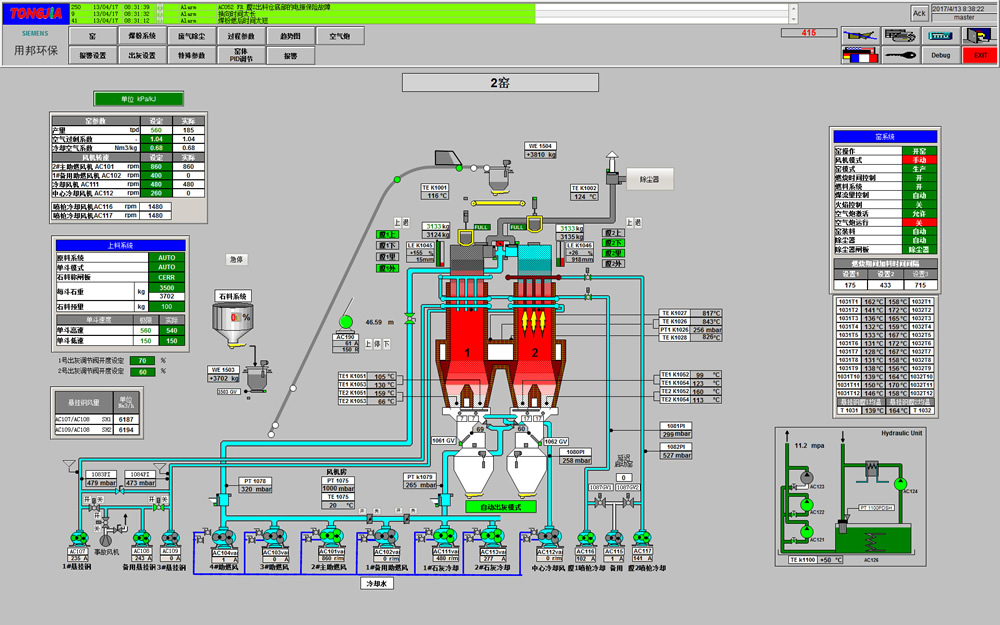

1. Double-chamber lime kiln, two kiln chambers alternately calcine with high output.

2. The function of double-chamber calcination to lengthen the preheating zone and cooling zone.

3. Calcined lime has high activity, energy saving and environmental protection, and reduces combustion energy consumption.