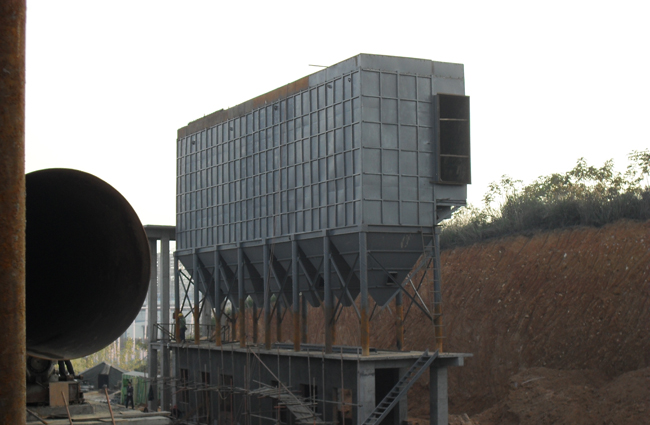

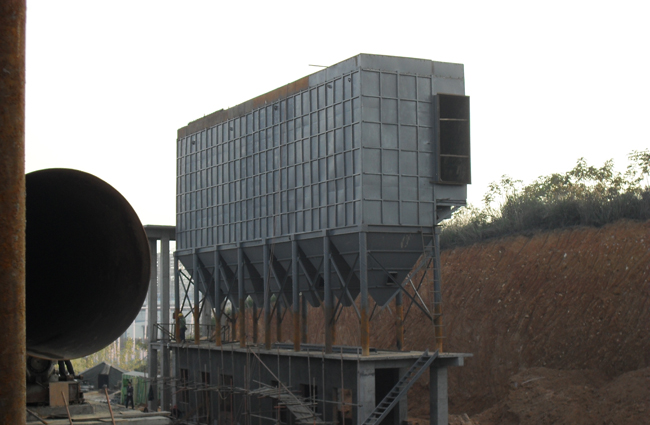

Description

LQMC / YL series of low pressure long bag pulse bag filter is designed for a variety of industrial furnace flue gas dust removal system designed efficient dust removal equipment. Design and manufacture and application of bag filter to deal with high temperature, complex flue gas engineering and technical experience, for industrial furnace flue gas high temperature, large handling air volume characteristics, the use of the resistance High temperature, anti-corrosion, anti-condensation filter; module combination, unique low resistance filter bag structure; heat distortion, high air tightness design; low pressure pulse cleaning and other advanced technology. High filtration efficiency, low running resistance, long bag life, easy maintenance and use. Can be based on industrial furnace smelting process characteristics for local adjustment to meet the needs of a variety of furnace flue gas dust.

Main technical features:

Model: LQMC / YL series of low pressure long bag pulse bag filter

Filtration area: 350m2 ~ 15000m2

Processing air volume: 20000m3 / h ~ 900000m3 / h

★ using the international advanced proprietary ladder into the air flow distribution technology and ash bucket diversion technology, instead of the traditional inclined tube into the air way. Not only can make the air distribution evenly, but also can effectively reduce the resistance of equipment to extend the life of the filter bag.

★ design using dual valve plate, multi-tube air-cooled, complement the wind proprietary technology to ensure that the system zero leakage. To ensure long-term efficient, reliable, stable operation.

★ dust collector ash bucket design using anti-stacking technology and a reasonable way of bag, according to the characteristics of high temperature flue gas, can effectively prevent the accumulation of smoke dust, bypass.

★ design using large-capacity pulse jet combination technology, can more effectively achieve efficient cleaning.

★ filter bag assembly is convenient, good sealing, to achieve the machine outside the bag.

★ The introduction of foreign automation bag cage production line, bag cage surface with galvanized treatment, the surface smooth and no burr, reliable quality, beautiful appearance.

★ use of industrial furnace for filter, the normal life of the filter bag more than 2 years.

★ imported pulse valve, the wearing parts of the diaphragm life of more than 100 million times.

★ with differential pressure, timing, manual three control methods of advanced controller, the dust collector equipment, cleaning pulse valve, off-line valve, ash removal device, material level, temperature and other comprehensive control.

★ Mainly used in steel mills, all kinds of metal ore, alloy smelting, etc., to ensure that the national requirements of the discharge standards below 50mg / Nm3.

★ The series of dust collector is mainly used for a variety of industrial kiln dust exhaust purification, such as electric furnace, medium frequency furnace, reverberatory furnace, bottom blowing furnace, smelting furnace and other industrial furnaces, in steel, copper smelting, lead smelting, alloy Smelting and other metal smelting furnace technology widely used.

More information of the High Temperature Bag Filter PLS contact me:

TEL:0086 18568631888

WS:0086 13663831568

E-mail:tongjiagroup@163.com