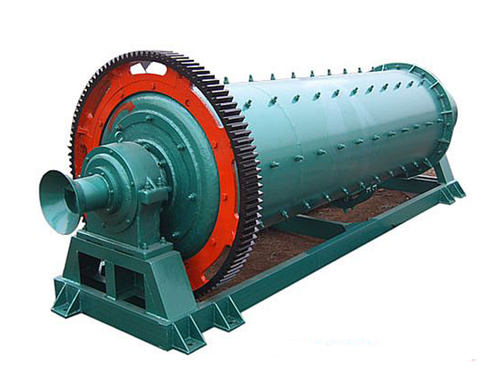

The ball mill belongs to the mineral dressing equipment, its main function is to grind all kinds of metal ore, but the user generally reflects its working efficiency is lower than the designed output in the production process. How can such problems be solved? This paper analyzes and introduces the following aspects in detail:

1. Equipment configuration is low

There is a close relationship between equipment configuration and production capacity, and the higher the production capacity,

The efficiency of its work will be higher, and at this time the output can meet the user's standard, and on the other hand, the inefficient phenomenon will appear, so the user must choose the equipment with high configuration in the process of purchasing equipment so that the problem of low efficiency will be solved.

2, poor performance performance

If the equipment is prone to problems in the course of operation, then it will inevitably affect production, and the performance of the equipment has a direct relationship with the motor. Only good motors can fundamentally enhance the operation stability of the equipment. And the reliability is higher in the actual production process, which provides the hardware foundation for improving the efficiency of the equipment.

3. The problem of failure rate

The production capacity of equipment with a high failure rate must not be high. The failure of the equipment is caused by technical reasons. Generally speaking, the equipment with high technology content will have a higher scientific and technological content. On the other hand, the low-technology equipment is not enough to meet the normal production of users, which is one of the main reasons for its working efficiency.

4, user operational aspects

Due to the improper operation of the users, the production capacity of the equipment will drop sharply, so it is necessary to effectively enhance the operational proficiency of the users. Therefore, each manufacturer has increased the level of training for its employees. In this process, the production capacity of the equipment has been greatly increased, and the output is in line with the actual production standards of the users, and the users are quite satisfied with this.

5. External environmental factors

The change of the external environment will also lead to the inefficiency of the equipment, because the environmental temperature will have a great impact on the production. The temperature is too high or too low for the operation of production. Therefore, it is necessary to install a temperature controller on the equipment. And the temperature should be detected effectively before starting the machine, so as to provide the necessary preparation for improving the production efficiency of the equipment.

More information about the Ball Mill , PLS contact me:

TEL:0086 18568631888

WS:0086 13663831568

E-mail:tongjiagroup@163.com